Injection moulding machines

Plastic molding is the process of shaping plastic using a rigid frame or mold. The technique allows for the creation of objects of all shapes and sizes with huge design flexibility for both simple and highly complex designs. The concept of plastic molding is placing liquid polymer into a hollow mold so that the polymer can take its shape, often with various ranges of pressure and heat required.

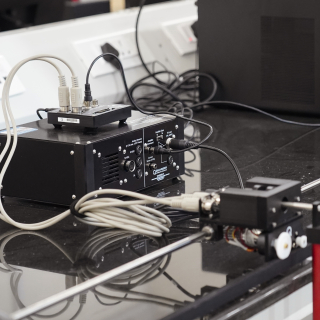

Injection molding is a manufacturing process for producing parts from both thermoplastic and thermosetting plastic materials. Molten plastic is injected at high pressure into a mold, which is the inverse of the product's shape. After a product is designed, usually by an industrial designer or an engineer, molds are made by a mold maker (or toolmaker) from metal, usually either steel or aluminium, and precision-machined to form the features of the desired part. Injection molding is widely used for manufacturing a variety of parts, from the smallest component to entire body panels of cars. Injection molding is the most common method of production, with some commonly made items including bottle caps and outdoor furniture. Injection molding process and different machine parts are shown in the figure below.

Quantity avaiable:

Semi automatic injection moulding machine: 01 no.

Manual injection moulding machine: 01 no.